Electric Signs

Walgreens Returns to Times Square

The Slash hits the heart of the Crossroads of the World.

Published

15 years agoon

Walgreens has a new prescription for Times Square, said Barry Winston, a sign consultant who specializes in Times Square signage. “And that includes a stunning LED display that is acknowledged as the largest, single, LED spectacular in Times Square,” Winston said.

Winston acquired both the LED manufacturer and the installer who mounted the displays around the “new” Walgreens’ location. The fact is, the nation’s largest drugstore chain has made an historic return to Times Square, in particular, One Times Square, the building it originally occupied from the 1930s through the 1970s.

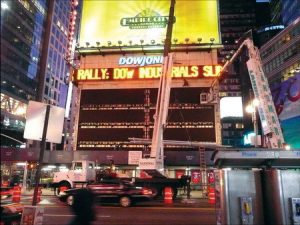

The Walgreens location sits at the exact heart of the Crossroads of the World. To ensure passersby notice the store, the company has covered the building’s sides and back with 17,000 sq. ft. of LED videoscreens.

“With its very dominating visual presence on the south end of Times Square, this spectacular will have great impact in expanding the marketing awareness of the Walgreens brand in Manhattan,” Winston said.

Meet the Slash

The Walgreens spectacular was designed by Gilmore Group (NYC), a multi-disciplinary design and branding firm. Gilmore Group principal Arthur Gilmore said, “Times Square is all about being lit up – and doing that with a lot of excitement. The creation of this LED spectacular presented several technical challenges, but perhaps the biggest challenge was an aesthetic one of creating a cohesive sign design for Times Square that would withstand the test of time to function aesthetically, now and far into the future, as Times Square continues to evolve.”

AdvertisementOne Times Square’s most visible north side, where New Year’s Eve audiences watch the Time Ball descend, was already covered with signage. Thus, for the other sides, Gilmore Group conceived a unique, spectacular package that would make it visually competitive with all the neighboring spectaculars and compelling enough to engage the attention of passersby, day or night.

The solution: a display system that begins at ground level and ascends diagonally to the top of the building. The main design, referred to as the “Slash,” begins as a diagonal line that starts at the base of the building, below the zipper (an electronic message center originally installed in 1928), and extends past the zipper to the top edge of the main building tower. An open space sits between the lower half of the building and the main tower, where the LED sign continues onwards to the top edge of the building crown. At the base of the building, where the LED sign begins, it wraps around the building. The signage then continues to the other side, where it creates another diagonal slash that follows from the base to the top of other side of One Times Square. (A separate LED display is on the back of the building.)

“No one has ever designed a diagonal sign of this nature on the side of a building as we have done,” Gilmore said.

As the Slash stretches across the building to its top level, the sign speaks to different audiences simultaneously, through multiple sightlines. The sign’s apex, at the upper portion of the building, serves as a tower beacon that’s visible to the furthermost, crosstown viewers. However, people who approach Walgreens see the display’s midpoint. Finally, as they near the building, the ground-level signage (the back-of-the-building LED display and the bottom-of-the-building displays) captures their attention.

Integrating building lines

AdvertisementArchitecturally, the Slash converges the lower building’s and its upper tower’s sightlines. Gilmore said, “It allows the eye to be fixed on a single sign location. Thus, as pedestrians approach the building, while there is a change in viewing angle, a portion of the sign is always easily visible to them.”

Furthermore, at the base of the building (its beltline), a second tier of LED video displays travels around the building from Broadway to Seventh Ave. Its full-color, ongoing promotions animate the street.

Gilmore said, “The ground-level LED displays look like the letter H on steroids, and a series of them are connected, end to end, around both sides of the building beltline. Because of their exaggerated shape, and the gaps in the signs, it creates both positive and negative space, which makes them more compelling to look at.”

Fabricating the Slash

D3 (Rancho Cordova, CA), which has installed several other grand spectaculars in Times Square (see ST, October 2007, page 90, and February 2008, page 76), fabricated the 17,000-sq.-ft. Walgreens display. Managing partners George Pappas, operations and manufacturing VP, and Jason Barak, sales and marketing VP, said D3 overcame several challenges mounting the spectacular to the building.

AdvertisementDiagonally mounting each LED sign panel on the One Times Square building wall impacted the structural loading of the Slash segments. Because each LED sign frame was diagonally mounted, each panel’s weight load changed its anchor point on the building wall. Pappas explained that, unlike a square or rectangular sign, where the weight loads are equally dispersed, anchoring a large, diagonal sign panel to a building wall incurs dramatic weight differences.

Barak also said, once the Slash was completely installed, several issues with the sign’s visual presence remained, including creating a consistent look over several different sign pitches and expanding the display’s sightlines for extreme viewing angles. D3 also relocated some of the displays’ power supplies outside their sign cabinets to facilitate access.

As a result of the Slash’s extensive height (it tops off at 350 ft.), the D3 LED screens have different pitches, depending on their viewing height. At the uppermost point of the building, the Slash has a 24mm pitch; its central segment is 12mm pitch; and the lowest segment, at ground level, is 10mm pitch. Because viewing distance affects image resolution, pixel pitch diminishes the closer it comes to street level.

Thus, the Slash’s content provider designs content on an LED sign with different pitches, depending on the display’s location. The solution, according to Meric Adrianson, D3’s systems and operations director, was to create a 10mm “universal standard” pitch for creating content for the entire sign package despite the pitch the content is streaming toward.

Barak explained: “Because pedestrians see the Walgreens spectacular from various viewpoints [near and far] around One Times Square, D3 came up with a ‘one display fits all sightline solutions’ approach. D3 created an extreme-viewing-angle louver, which allows you to stand right in the middle of Broadway and watch the content streaming up and down the Slash without any distortion.

“In viewing a conventional LED display, any time you move away from the preferred viewing angle, the image begins to break up through distortion. With our extreme-view louver, you can almost get a 180° view of the sign’s content as you look at the Slash from wherever you are in the vicinity of the Walgreens displays. Thus, people near ground level have one viewing angle [close up], and others who are farther away have their own viewing angle.”

Data/power separation

The upper portions of the Walgreens spectacular stand at least 300 ft. up the sides of One Times Square. The height alone posed maintenance/service-access problems in terms of power/data connections to each sign segment.

Most LED-display service calls deal with replacing or repairing LED power supplies. Because the LED cabinet sections were already mated against the sides of the building wall, D3 separated power and data lines from the cabinets and placed these sign components along the opposing window sills on every other floor in One Times Square.

“This was done only for the middle Slash section,” Barak said, “and this allows the maintenance of the sign cabinets, when necessary, to be done from the inside of the building without using boom trucks or overhead platforms. It’s more efficient, and it became a safety-improvement solution as well. Also, it became a more cost-effective way of serving the sign.”

Separating the power supplies from their display cabinets reduced the heat inside the cabinets at least 30%. “We therefore had a more efficient cooling of whatever residual heat was left in the cabinets,” Barak said.

In terms of prepping sign components for installation, Pappas noted, once the LED-display sections were assembled at D3’s Rancho Cordova headquarters (in northern California), specific sign modules were delivered from the West Coast to Times Square on a complex shipping schedule, on successive weekends, so Landmark Signs and Electrical Maintenance Corp. (NYC) could install each Slash sign segment.

Hanging the Slash

Landmark Signs, which manages and operates the descent of the New Year’s Eve Ball, handled the placement of all the Slash sign components on the sides of One Times Square. Landmark principal Tony Calvano said the installation steps began by drilling thousands of penetrations into the building, which was followed by the insertion of an equal number of epoxied anchor bolts where the Slash would be attached.

Once the anchor bolts were placed, individual display sections were lifted onto their designated locations. After the panels were situated, power and data lines were connected from display cabinet to display cabinet, and from the display cabinets to their equivalent power supplies.

The Walgreens sign’s continuous length required a series of three boom truck/cranes to install the sign components. For the signs at the top end of the upper tower, Landmark used a truck with a 370-ft. boom, or 30 ft. taller than the building.

Calvano said, “Aside from the usual permits [street placement, street closure, etc.], the sign-

installation location presented an unusual challenge of being in one of the busiest traffic locations in New York City. Despite the location, the sign install followed the usual preparation of bringing in the truck crane and a separate flatbed with the sign-panel components. This required street-lane closures to park both vehicles during the unloading and lifting of the signs, and anchoring them to the sides of the building.”

Calvano emphasized each “lifting-install” session followed a tight weekend schedule midnight to 8 a.m., with two hours each day to set up the truck, and another two hours to strike, which left Landmark with a four-hour work window to place panel segments.

To complete the Slash installation, depending on the building height, three different cranes were used. At ground level, Landmark had a 125-ton crane, which reached up to 17 stories; for the mid-level, they had a 300-ton crane (which serviced up to 27 stories); and, finally, for the top of the building installation, the 600-ton crane, the biggest mobile crane available, completed that part of the sign installation. Altogether, they needed 14 weekends to install all parts of the Slash on the sides and back of One Times Square.

A dash of the Slash

Walgreens has returned to Times Square with an outstanding spectacular that intimately connects it to midtown Manhattan and beyond. The drugstore chain has planted its flag in one of NYC’s most famous buildings with a world-class spectacular that promotes its brand, merchants and product offerings. That’s a sign of a great prescription for success.

Louis M. Brill is a journalist and consultant for high-tech entertainment and media communications. He can be reached at (415) 664-0694 or louisbrill@sbcglobal.net

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

INX Promotes Three to Vice President

6 Sports Venue Signs Deserving a Standing Ovation

Hiring Practices and Roles for Women in Sign Companies

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Tip Sheet4 days ago

Tip Sheet4 days agoAlways Brand Yourself and Wear Fewer Hats — Two of April’s Sign Tips

-

Business Management2 weeks ago

Business Management2 weeks agoWhen Should Sign Companies Hire Salespeople or Fire Customers?

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs Award Winners Excel in Diverse Roles

-

Real Deal5 days ago

Real Deal5 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks1 day ago

Benchmarks1 day ago6 Sports Venue Signs Deserving a Standing Ovation

-

Editor's Note1 week ago

Editor's Note1 week agoWhy We Still Need the Women in Signs Award

-

Line Time2 weeks ago

Line Time2 weeks agoOne Less Thing to Do for Sign Customers

-

Product Buying + Technology1 week ago

Product Buying + Technology1 week agoADA Signs and More Uses for Engraving Machines