Electric Signs

One Block at a Time

Capital Mfg. helps restore Atlantic City

Published

16 years agoon

Capital Mfg. (Lansdale, PA), one of the largest, privately held, U.S. sign companies, produces signage systems, custom-engineered architectural and ornamental structures, environmental graphics, interactive displays and specialty lighting. The company employs a staff of approximately 50 fabricators and designers within its 45,000-sq.-ft. facility.

Capital’s manufacturing capabilities recently helped the company win and complete a highly diverse and interesting project on the Atlantic City (NJ) Boardwalk.

Funded and directed by the New Jersey Casino Reinvestment Development Authority, the $100 million Atlantic City Boardwalk Façade project aims to revitalize the Boardwalk’s role as a tourist attraction in Atlantic City by evoking the excitement visitors experienced during its heyday in the early 20th Century. The plan will be implemented through several phases for the next few years, restoring Boardwalk storefronts, one city block at a time, along designated sections of the seaside structures.

The project’s second phase, which Capital produced, refurbished the Boardwalk’s 1500 block and encompasses the entire frontage between New York and Kentucky Aves. Capital’s successful bid green-lighted the company to manufacture and install custom signs, canopies and ornamental structures for the 15 storefronts. The entire project dictated unique shapes, structures and lighting that required custom engineering, construction and installation.

AdvertisementGetting it together

Capital’s management team for the Boardwalk renovation included Piero Cappelli, Capital’s owner and CEO; Steve Appelbaum, the sales VP for Capital’s Atlantic City Div.; and myself as project manager. Essentially, the project’s timeline included the following seven-step process:

• Developing a proposal for the bid process;

• Shop drawings upon being awarded the project, which required the architect’s approval;

• Site surveys, which gauged the signs’ appropriate size and installation methods;

• Ordering materials (not a task done lightly, given surging aluminum and steel prices; materials costs have risen 30 to 40% in the last few years);

• Fabrication;

• Permit applications; and

• Installation.

The project’s oceanfront location created numerous, unique challenges. All sign structures required engineering to withstand a 150-mph wind load, which dictated using steel to produce all structural-support components. We used 1⁄8-, 3⁄16- and 3⁄8-in.-thick steel, which depended upon each project’s size and exposure to the elements. To combat the environment’s corrosive salt and sand barrage, we applied a powdercoated exterior to bolster the metal’s strength.

Additionally, the project required special permits, engineering, site preparation and stringent installation logistics. We obtained special Boardwalk permits that allowed restricted installation access to accommodate the site’s limitations.

Advertisement

Installers laid wood planking, which they also removed daily, across the entire Boardwalk area affected by our project, because our work trucks couldn’t travel directly on the Boardwalk’s aging planks. Work needed to be scheduled very early in the morning in order to finish each day by noon to accommodate Atlantic City’s tourist traffic.

Because of the Boardwalk’s weight limitations, the Atlantic Galleries’ copper dome required a 300-ton crane to be positioned behind the rear of the building in order to lift the dome up and over the building for the final installation. Although we didn’t have to meet such a ponderous weight requirement, we needed such a large crane’s reach to accomplish the installation.

Material choices

Aluminum – we used the same thicknesses as with the steel – and Plexiglas® acrylic comprised the primary construction materials for the exterior signage. Using our Gerber 408 and MultiCam 3000 Series CNC routers, we machined the substrates and fit the Plexiglas within the routed-out aluminum. We developed these elements using SolidWorks 3-D software.

The project’s architects and lighting designers specified unique requirements and characteristics for each storefront application. Every canopy and awning featured Color Kinetics’ ColorBlast® RGB LED light fixtures that flooded the building facades with programmable, changing light.

AdvertisementChristina Spangler, principal of LDC (Egg Harbor Township, NJ) and the project’s lighting designer, incorporated the programmable fixture and remained closely involved throughout the project to ensure cohesive lighting across the block. Each storefront could be programmed for its own light show or work in sequence with others for a unified display. Spangler and a Color Kinetics representative collaborated in the programs’ creation.

Project highlights

We fabricated the Lucky Lou’s Tattoos marquee sign canopy to resemble an old movie theatre, which entailed installing hundreds of LED lights under the canopy, to project light onto the Boardwalk below. Hundreds of LEDs installed around the border illuminate the top of the sign. Low-voltage LEDs will provide up to 100,000 hours of lighting, a 10-fold-longer service life versus standard-voltage halogen or compact-fluorescent bulbs.

Capital constructed a colorful starburst design, which faces the Boardwalk, from aluminum, with faux-finished stained glass that’s internally illuminated with standard, high-output, fluorescent lamps. To create the faux finish, we output a digital print on our 64-in. Seiko Infotech Color Painter and applied it to the sign’s second surface.

To identify James’ Salt Water Taffy, Capital constructed a large canopy sign that projects over the Boardwalk. Installers fit the lights under and around the sign’s entire border. We also built and installed a blade sign that projects off the wall over the canopy. The canopy measures 20 x 8 x 9 ft., and the blade sign spans 10 x 4 x 1 ft. We installed low-voltage LEDs around the entire border on both sides of the blade sign.

We built Atlantic Galleries’ 20 x 20 x 10-ft. dome, which required the behemoth crane for installation, features 1,000 color-changing LED lights with a DMX controller that allows each light to be controlled or to run in a sequence.

The Atlantic Souvenirs shop features a very unique “eyebrow” canopy with a copper-patina faux finish on aluminum. We handpainted this patina look in our shop by mixing Matthews acrylic-polyurethane color in our paint booth and adding layers to create a finished appearance. The canopy’s fabrication was especially challenging, because the canopy’s front elevation required a different radius than the side profile. We conveyed our requirements into our AutoCAD 2008 drafting software that drives our metal-rolling, cutting or bending equipment.

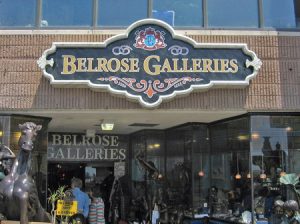

Bellrose Galleries’ sign package includes a sign cabinet constructed with aluminum finished with a faux, white-marble border. The sign features decorative trim and filigree accents with a routed, Plexiglas face and a faux, black-marble finish. The sign is internally illuminated with standard, high-output fluorescent lamps, with an LED channel built around the face to provide a halo effect.

And, finally, Capital identified Godfathers Pizza with a blade sign that projects off the wall and was installed over the left side of the canopy. We installed two rows of low-voltage, LED bulbs around the border.

The project required approximately nine months, and we finished by last Memorial Day, in keeping with the Authority’s deadline. Value-engineering sign solutions, especially with such complex projects, is a challenge we always accept to fulfill customers’ needs and wants. We’re currently bidding on future phases of the Boardwalk’s redevelopment, and we’re optimistic we’ll resume our role in the redevelopment of a national treasure.

Equipment and Materials

Lighting: Colorblast programmable RGB LEDs, from Color Kinetics (Boston), (888) 385-5742; low-voltage LEDs, from Color Kinetics.

Paint Systems: Acrylic-polyurethane paint from Matthews Paint Co. (Pleasant Prairie, WI), (800) 323-6593.

Plotters: Graphtec 64-in. Cutting Pro FC7000-160, from Graphtec America Inc. (Santa Ana, CA), (888) 318-3247; SmarTrac 42- and 54-in. cutting plotters, from Ioline (Woodinville, WA), (425) 398-8282.

Powdercoating: Powdercoating booth, from Tiger Drylac USA Inc. (Ontario, CA), (800) 243-8148; Industrial drying oven, from Mahan Oven & Engineering (Spartanburg, SC), (800) 809-6120.

Printers: Sixty-four-in. Color Painter 64S, from Seiko I Infotech (Escondido, CA), (760) 781-5200, and 64-in.-wide DesignJet 500 solvent-ink printer, from HP (Palo Alto, CA), (800) 752-0900.

Routers: MultiCam 3000 Pro Series CNC router, from MultiCam LP (Dallas), (972) 929-4070; Gerber Advantage 200 CNC router from Gerber Scientific Products Inc. (South Windsor, CT), (800) 222-7446.

Software: AutoCad 2008 drafting software, from Autodesk (San Rafael, CA), (415) 507-5000; Solidworks 2008 3-D software, from SolidWorks (Concord, MA), (978) 371-5011; Corel Draw X3, from Corel Corp. (Ottawa, ON, Canada), (800) 772-6735; Illustrator CS and Photoshop CS, from Adobe (San Jose, CA), (408) 536-6000; Flexi Expert 7.6v2, from SA Intl. (Philadelphia), (800) 229-9066; and Neon Wizard 5.1 sign-lighting software, from Aries Graphics (San Marcos, CA), (800) 294-7273.

Substrates: Aluminum and steel sheet, from sheetmetal shops; Plexiglas® acrylic, from Altuglas Intl. (Philadelphia), (800) 523-7500.

About Capital Mfg.

Headquartered in Lansdale, PA, just outside the Philadelphia metropolitan area, Capital Manufacturing has been in continuous operation for more than 60 years. The company employs 50 skilled professionals and maintains a 45,000-sq.-ft. facility equipped with CAD and CAS equipment for the design, fabrication, installation and maintenance of the many unique projects it manufactures.

Capital is headed by Piero Cappelli, CEO/owner and powered by a team of highly experienced, signmaking professionals who provide innovative thinking and a hands-on, can-do attitude. Capital takes great pride in the products and services it provides, and prioritizes customer satisfaction. The company’s clientele include Armstrong World Industries, PNC Bank, the Newark Airport, Citizens Bank Park, FedEx Stadium and the United Center. For more information, contact the company at (800) 253-2843 or visit www.capitalpa.com.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Church Sign Found After Being Stolen From Cemetery

PRINTING United Alliance Forms Strategic Partnership with ASI

The Joy of Working

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Photo Gallery1 week ago

Photo Gallery1 week ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks agoWhy Are Signs from Canva so Overloaded and Similar?

-

Paula Fargo7 days ago

Paula Fargo7 days ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal4 days ago

Real Deal4 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks2 weeks ago

Benchmarks2 weeks ago6 Sports Venue Signs Deserving a Standing Ovation

-

Photo Gallery7 days ago

Photo Gallery7 days ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Brandi Pulliam Blanton

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Alicia Brothers