Electric Signs

A Majestic Marquee

Custom Finishers creates scintillating signage for the Regal Times Square.

Published

16 years agoon

In Times Square, few frontiers or taboos remain for signage. As evidenced by the numerous ST spreads in recent years (particularly those authored by our resident Burning Man devotee, freelance writer Louis M. Brill), the perpetual one-upmanship – to unveil the biggest, most colorful or most hyperkinetic dynamic display in the United States’ cultural epicenter – has created an almost unparalleled signage marketplace.

In this environment, every sign must strive for the extraordinary. Consequently, the Regal Entertain-ment Group sought a distinctive sign program for its Times Square multiplex. The result? Nearly 2,000 sq. ft. of environmental graphics created by Levittown, PA-based Custom Finishers Inc. that includes a scintillating light show and a winsome synthesis of a vintage movie marquee and new-school innovation. Here’s the lowdown on Custom Finishers’ role in furthering Times Square’s transformation from a run-down, red-light district into a beacon of activity.

From conception to construction

The Knoxville-based Regal Entertainment Group, which owns the cinema, hired Custom Finishers to update the theatre, which Loews Theatres had previously occupied. Bill Lockett, Custom Finishers’ sales VP, said Regal aspired to make this theatre a showplace.

“Most of Regal’s locations are large, freestanding multiplexes,” he said. “For this unique, one-off location, they were willing to consider new strategies to make it stand out within its environment.”

Unfortunately, time was not on the shop’s side. Custom Finishers won the job in early spring, and Regal required an ironclad commitment they could finish the job in time for Spider-Man 3’s blockbuster summer opening. With a nine-week turnaround, they promptly began creating a prototype channel letter and arranging meetings with project contributors. In less than two weeks, they’d developed a prototype channel letter which Regal gave an enthusiastic thumbs-up.

AdvertisementWorking with Regal and NYC’s 42nd St. Development Corp., Custom Finishers refined the concept. Regal wanted a dynamic location, because a competing theatre resides across the street. The original canopy had been covered over without the Development Corp.’s consent. The company’s lead designer, Keith Denny, worked with them to recreate the original canopy, based on a photograph of the original Loews Theatre marquee.

“Initially, [the Development Corp.] wanted us to completely replicate the original sign,” Lockett said. “But, we when showed them drawings of how the blade sign and marquee modifications would mix the old with the new, they eagerly approved our proposal.”

The sign’s electrical power required nine, 1½-in., sealed conduits (each contained 20 circuits) and one, 4-in.-diameter bundle of data cables. However, given the ponderous sea of electrical connections housed within the building, identifying the appropriate circuits for the sign’s lighting would prove challenging. Fred Wenclawiak, Custom Finishers’ manufacturing VP, created a “low-tech” solution. Onsite prior to installation, he created a lightbox, with 20 bulbs for each circuit, and sent it up to the installation area on a high-reach crane truck. Installers tested the circuits until they successfully lit the box. Thus, when the components were ready, they immediately found the “juice.”

“They could’ve paid an electrician to diagnose the right circuit, but it would have cost a significant amount of money, and an electrician would’ve lacked the equipment to get to the elevated site,” Lockett said. “[Company president] James Gross was onsite helping with the installation; this was a hands-on project for everyone.”

Another significant hurdle involved removing the original sign, which comprised a blade sign with older-generation, flashing LED displays and marquee with incandescent chasing lights below. Lockett said modifying the Regal’s desired font, Goudy, to accommodate the LED installation requirements, while remaining legible, was difficult.

Advertisement“The letter and stroke thickness was critical to create a successful design intent, but Goudy’s thin strokes on several letters could have posed a challenge to optimal module functionality,” Denny said. “To make sure the light shows could function in horizontal or vertical formats, we worked with Regal’s director of signage services, Kate Kornhaus, to make sure the letter and lighting modifications conformed to their company’s corporate-branding guidelines.”

Custom Finishers also redesigned the canopy to better display an original design that David Rockwell, a noted architect and environmental designer, had produced with his company, the Rockwell Group. Intricately designed, 5 x 8-ft. fiberglass panels, with decorative cornices, offered a timeless, sophisticated design that subtley celebrate the city’s historic moviehouses. Over the marquee’s lifespan, these elements had been replaced – Custom Finishers restored them, which entailed filling in and coating the panels in several places. Internal, fluorescent cove lighting illuminates this sign layer.

Bright lights, big city

One key marquee change involved replacing the prior Color Kinetics (Boston) RGB LED modules with its new iColor MRg2 modules. Their key features include variable beam angles – a 24° setting for pinpoint illumination and a 60° angle for broader light transmission – 16.7 million colors with variable light intensity, and its Smartjuice® that multiplexes (routes multiple data streams into one signal) incoming power and data into an outgoing, two-wire circuit that fits conventional LED fixtures and sockets.

Jack Tusman, Custom Finishers’ IT director, said the company used Color Kinetics’ proprietary software to program and set up the sign’s illumination. The system incorporates 12 Ethernet switches to direct the 2,200 MrG2 modules and 180 power supplies.

To begin programming the sign, Custom Finishers assigned a unique “address” to each power supply. Next, each module received an address and a specific position within each letter, which allows individual control of any module.

AdvertisementTo program the light shows, Tusman followed the software’s basic programming steps and, when mixed with other programs – for this project, he used Adobe’s Flash C2 – achieved unique effects, such as kaleidoscopes, fire and other programmable animations.

“The sign features 10 different programs that can be switched with a push of a button on the DMX controller system,” Tusman said. “Each of the programs runs for 10 minutes and then restarts on a continuous loop.”

“This work requires several different permits from various [NYC] governmental agencies to complete install the signage and arrange street closures so we can work,” Lockett said. “Removing the original blade sign was especially challenging – because of its size and location, we required off-hours work and additional work crews.”

Lockett said getting permits in the city was difficult given the tight timeframe and city-government bureaucracy: “We needed approvals from the owner, the Development Corp. and the city to erect a sign or make any changes. To save time, we filed for a self-certification permit, which allowed our engineer to review, seal and stamp the documents and oversee the city’s inspection. This allowed us to have our permits in hand within two weeks.”

Although the city stipulated working between the hours of midnight and 10 a.m., “the city that never sleeps” still posed significant traffic challenges. Using vehicles large enough to reach the sign’s 100-ft.-tall apex requires directing pedestrians away from the work area. Lockett credits North Shore Neon Sign Co. (NYC) with the planning and implementation of the blade sign’s loading, rigging, transportation, erection and removal. Wenclawiak and Gross worked closely with them to coordinate the project.

To install the new canopy, Custom Finishers needed to erect specialty scaffolding to provide sufficient work area to complete the job. To identify the theatre, we installed temporary banners over the scaffolding.

The sign program entails the 60 x 16-ft. blade sign; a 40 x 12-ft. canopy; canopy signage that measures 32 x 10 ft.; a 10 x 4-ft. wall sign; and twin, 6 x 10-ft., Trans-Lux (Salt Lake City) LED messageboards.

Making a statement

Lockett said retrofitting a sign within an existing frame poses several challenges: “You don’t really know the level of wear and tear, or the construction quality, of the existing frame. In this case, the sign had to be virtually rebuilt on the existing steel frame. Custom Finishers replaced all back panels and performed major body work and repainting of the existing marquee.”

The Regal canopy sign comprises 4-ft.-tall channel letters encased within .080-in., red-painted, aluminum returns, fortified by a support-tube grid. To illuminate the sign, Custom Finishers employed EGL 15mm, exposed, ruby-red neon tubing powered by core-and-coil transformers inside each letter. To facilitate installation and maintenance, a junction box was installed below.

Because the modules and electronic components are vulnerable to heat, adequate channel-letter ventilation for the 8-ft.-tall, marquee letters was essential. Lockett said each letter contained two, 4-in.-diameter fans at the top of each letter, with, depending on the stroke, one or two fans at the bottom.

Below the channel letters, the shop installed a CNC-routed, aluminum face that reads “Cinemas.” For the second surface, the crew fabricated routed, push-through Plexiglas® acrylic copy. Internally, high-output, fluorescent ballasts light up the panel. Peachtree City Foamcraft (Shnecksville, PA) fabricated the router-cut, cascading accents made from 15-lb., HDU foam that add pizzazz to the canopy’s graphics.

To appropriately coronate the program, the design team created a 5-ft.-diameter medallion that features twin, inset, Lexan® polycarbonate crowns. Within a 1-in, black Jewelite® trimcap and a fabricated, aluminum channel, white LEDs backlight the crown and its encircling border. Engineers verified the columns that framed the marquee were sufficiently strong to support the medallions and the required installation hardware.

Lockett credits Gross and Rich Pearce, Custom Finishers’ shop manager, with keeping the shop’s staff on task to turn around the marquee channel letters within two weeks.

Sharpening the blade

The vertical blade sign required installation within an existing, retro-style, steel structure. To coordinate this structure, Custom Finishers painted the background blue using Matthews acrylic-polyurethane paint. Lockett said they removed the 15mm, novial-gold neon border tubing and replaced it with newer, comparable materials. To bolster the sign’s lifespan, they also replaced the connection plates and installation hardware that join the sign to its support column.

Programming the MRg2 modules proved challenging because each individual module (all letters on the two-sided sign contained 336 to 516 modules) required separate identification and mapping to Color Kinetics’ proprietary software.

Each module requires a unique, recognizable address for uninterrupted communication to the control panel. To avoid communication interference, LED-data cabling required separation from all other electrical wiring. The sign also contains a temperature-control system that shuts off during temperature extremes in order to protect system components, According to Color Kinetics, the modules function in ambient temperatures up to 104° F, or a surface temperature of 167° F.

Service with a smile

An important job component, Custom Finishers’ three-year service contract, covered bimonthly and as-needed maintenance of the entire blade and canopy signs, and included bulbs, electronics, Ethernet switches, neon, secondary wiring, fans and filters.

“We offer several service levels based on the project’s scope, the sign package’s value and customer expectations,” Lockett said. “Given the system’s prominent location and visibility, and the harsh urban conditions, such as vibration, exhaust fumes and regular building pressure washing. A complex project such as this requires a detailed maintenance contract.”

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Church Sign Found After Being Stolen From Cemetery

PRINTING United Alliance Forms Strategic Partnership with ASI

The Joy of Working

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Photo Gallery1 week ago

Photo Gallery1 week ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks agoWhy Are Signs from Canva so Overloaded and Similar?

-

Paula Fargo7 days ago

Paula Fargo7 days ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal4 days ago

Real Deal4 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Photo Gallery7 days ago

Photo Gallery7 days ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Brandi Pulliam Blanton

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Alicia Brothers

-

Signs of the Times1 week ago

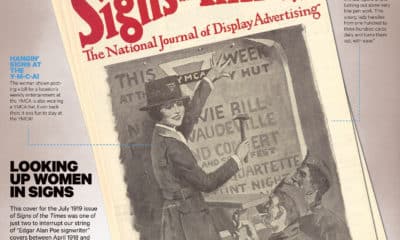

Signs of the Times1 week agoJuly 1919 Signs of the Times Cover Features Woman Installer