Electric Signs

Sign and Lighting Maintenance

Service what you sell

Published

18 years agoon

Manufacturing remains the primary focus of the sign business, and sales of new signs represent the lion’s share of all sign-company income. This production obsession creates a significant market in the field of sign and lighting maintenance. I wish I had a dollar for every time a customer told me that service after the sale was slow or non-existent. It’s not uncommon even for large, successful sign companies to drop the ball on service, leaving customers in the lurch. Therefore, if your sign company already owns service equipment, you can tap this source of additional profits.

Because the sign business is dominated by large-volume builders, those who seek to build a maintenance business face some resistance in the form of existing service contracts. Another challenge is the substantial number of "problem signs" that require constant service due to poor construction. But these obstacles shouldn’t prevent sign-service contractors from prospering in a world filled with electric signs and lighting fixtures. On the contrary, a sign company might discover a competitive advantage entering a lighting-maintenance field dominated by large electrical contractors with high overhead expenses.

Running the lights

To tap the sign-maintenance market, you must reach the customer when he needs service. An effective method to accomplish this is to perform nighttime lighting surveys. Most service contractors print promotional cards to hang on doors or place in mail slots (Fig. 1). The person distributing these cards should make a list with the name and address of each business contacted, so that follow-up phone calls can be made. It’s also important for the person who distributes the cards to record the type and approximate height of the sign(s) needing repair. The service mechanic must know in advance what type of equipment is required.

In large urban areas, sign companies can garner a substantial number of leads by "running the lights" in various districts on a regular basis. This is particularly true immediately following heavy rains or during cold weather. In addition to signs, parking-lot lighting is an excellent source of maintenance business. Automobile dealers and shopping centers frequently hire sign companies to service their large, pole-mounted fixtures. The sheer number of light fixtures maintained by these facilities makes this work quite profitable.

Ground rules

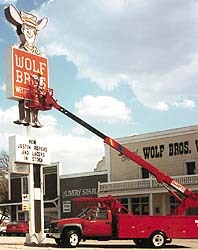

Equipment and know-how are crucial to operating a successful sign and lighting maintenance business. When I cut my teeth as a sign serviceman, carrying around a heavy, wooden A-ladder all day was the norm. Today, however, remote-controlled bucket trucks have largely replaced ladders for service, because they are safer and more efficient. By the time I can toss my old A-ladder onto the roof-rack of my van and tie it down, the serviceman with the bucket truck is already on the road. But service vans equipped with stepladders (Fig. 2) are still acceptable for jobs up to 15 feet high.

Carrying the proper supplies is critical for a profitable operation. Service trucks should be well equipped with lamps, ballasts, sockets and other electrical components normally found in electric signs and commercial lighting fixtures (Figs. 3 and 4). Customers don’t expect to be charged for time spent driving to local supply houses to pick up items not stocked on your service truck. Naturally, the better your truck’s storage areas are organized, the easier the service mechanic’s job.

It seems obvious to note that service mechanics must be experienced in all types of incandescent, fluorescent and neon-sign repairs. But it’s amazing how many inexperienced people are repairing electric signs today. Before sending a recently hired service mechanic out on a repair job, one of your experienced mechanics should be able to vouch for the person’s competence. Setting up an in-house training program with instruction by your experienced mechanics is an excellent way to expand your human resources. Conversely, sending inexperienced people out on jobs can cost more money than it earns.

Pricing strategies

Profiting from maintenance work depends on making every hour of the working day count. First, you need to deal with the common question, "How much do you charge to come out and give me an estimate?" After repairing dozens of similar signs, you can usually give customers ballpark estimates of the repair cost without inspecting the signs. It’s better, however, to quote the customer a flat-rate, inspection/estimate fee. You must establish a minimum charge for this inspection/estimate service. A good rule of thumb is to charge a two-hour minimum fee, because you must allow for travel time, as well as the time required to identify the problem.

Never offer free estimates for sign repairs. Estimating a sign repair requires sending your service vehicle to the customer’s place of business and opening the sign for inspection. This is much more costly than the free-estimate services offered by lawn-spraying companies and other consumer-service providers. Your company must recover the significant expenses of providing this service.

When you quote a price for the estimate, always advise the customer that, if he opts to repair the sign immediately (on the same trip), the labor and equipment to troubleshoot the sign will be included in his total price. This gives your client an incentive to approve the quoted repairs. It’s also very important to inform the customer that your company intends to repair the sign properly and completely, so that it will not require additional repairs next week or next month.

Service contractors typically establish hourly rates that include both labor and equipment charges. In most areas of the country today, hourly rates for a 30-foot bucket truck and service mechanic range from $45 to $65. For crane-mounted buckets (or extending ladders attached to booms) with higher reach, rates increase accordingly. Large cranes or personnel lifts that service signs higher than 50 feet typically require two-man crews, and hourly rates in most areas range from $80 to $100. In addition to your desired profit margin, these hourly rates must include the total hourly cost of equipment and labor. Hence, you must estimate how much it costs your company per year for the equipment’s purchase, maintenance, insurance, licenses and fuel. Your accountant is the best source of information for costing labor, truck and equipment expenses. Job-costing programs are also available through various suppliers of business software. Once you have a reliable estimate of the annual cost to operate a given piece of equipment, you can calculate the appropriate per-hour cost to build into your rates.

Pricing strategies for maintenance materials and supplies are quite diverse. Some companies charge "book value" (list price) for lamps, ballasts and other electrical components. During my years in the maintenance business, however, I used "keystone pricing." In this method, the customer’s price for parts equals twice your cost. If I paid $4.25 for each F96HO-CW lamp, my unit price to the customer was $8.50. This price was adequate to return a fair profit, but was still significantly less than the list price of the lamp.

When bidding large maintenance projects (for example, repairing all the light fixtures at a major car dealer), it’s effective to provide the customer with per-unit prices that include all labor, equipment and materials. This allows your client to decide how much of the proposed work fits into his current maintenance budget. Does the owner want to repair 50 lights, 75 lights or 100 lights? Compared to the all-inclusive prices quoted by some lighting-maintenance companies, this flexible approach can be quite appealing to customers.

The higher cost of High Intensity Discharge (HID) lamps and ballasts commonly used for parking-lot lighting allows some discounting from the keystone price. For example, if you sell twenty 1,000-watt metal-halide ballasts to a car dealer, and the ballasts cost $105 each, your unit price might be $185 instead of the full keystone price of $210. Another option for very large projects involving hundreds of units is to charge the keystone price, but to also include labor and equipment. In general, the larger the lighting project, the more you can afford to discount to meet competition.

Warranties

With good reason, most sign users have low opinions of warranties. Frequently, sign builders fail to provide acceptable warranty service. Because ballast and transformer manufacturers offer two-year warranties, however, there’s no reason why you shouldn’t pass this benefit along to your customers. When I installed new ballasts in my customer’s signs, I always recorded the warranty-expiration date on the invoice, and informed the client that the warranty included replacement cost only, not labor and equipment. By taking the time to give your customers this added benefit, you reinforce your good reputation.

A salesman sold it

Many opportunities exist to establish or expand sign-and-lighting maintenance businesses. But a strong, consistent sales effort is just as important in selling maintenance as in selling signs. Like sign sales, selling maintenance service involves a continuous cycle of identifying and contacting leads at the appropriate times. The ultimate goal is to optimize the use of your firm’s equipment and labor. Every sign-company manager knows that sign projects don’t break down neatly into eight-hour increments. Adding service jobs to your crews’ daily schedules is an excellent way to extend those half-day excursions that reduce efficiency.

Some sign companies still view maintenance as a necessary evil, but with proper organization, equipment and job scheduling, service can become an important part of your annual profit picture. "Diversification" has become a buzzword in the industry today, as sign companies seek ancillary enterprises. Maintenance can be an important part of this mix.

SPONSORED VIDEO

Introducing the Sign Industry Podcast

The Sign Industry Podcast is a platform for every sign person out there — from the old-timers who bent neon and hand-lettered boats to those venturing into new technologies — we want to get their stories out for everyone to hear. Come join us and listen to stories, learn tricks or techniques, and get insights of what’s to come. We are the world’s second oldest profession. The folks who started the world’s oldest profession needed a sign.

You may like

Church Sign Found After Being Stolen From Cemetery

PRINTING United Alliance Forms Strategic Partnership with ASI

The Joy of Working

Subscribe

Bulletins

Get the most important news and business ideas from Signs of the Times magazine's news bulletin.

Most Popular

-

Photo Gallery1 week ago

Photo Gallery1 week ago30 Snapshots of the 2024 ISA Sign Expo

-

Ask Signs of the Times2 weeks ago

Ask Signs of the Times2 weeks agoWhy Are Signs from Canva so Overloaded and Similar?

-

Paula Fargo7 days ago

Paula Fargo7 days ago5 Reasons to Sell a Sign Company Plus 6 Options

-

Real Deal4 days ago

Real Deal4 days agoA Woman Sign Company Owner Confronts a Sexist Wholesaler

-

Benchmarks2 weeks ago

Benchmarks2 weeks ago6 Sports Venue Signs Deserving a Standing Ovation

-

Photo Gallery7 days ago

Photo Gallery7 days ago21 Larry Albright Plasma Globes, Crackle Tubes and More

-

Women in Signs2 weeks ago

Women in Signs2 weeks ago2024 Women in Signs: Brandi Pulliam Blanton

-

Women in Signs1 week ago

Women in Signs1 week ago2024 Women in Signs: Alicia Brothers